What drives an athlete forward? The constant ambition to progress, push limits and make every effort count. Billerud shares the same drive – we’re relentlessly optimizing the use of every fiber and the way we produce and transport our products. By always refining and improving, we empower our customers to achieve their goals in terms of efficiency, innovation and sustainability.

Always refining, always improving. Just like an athlete.

ATHLETIC AMBITION #1:

Making the most of every fiber

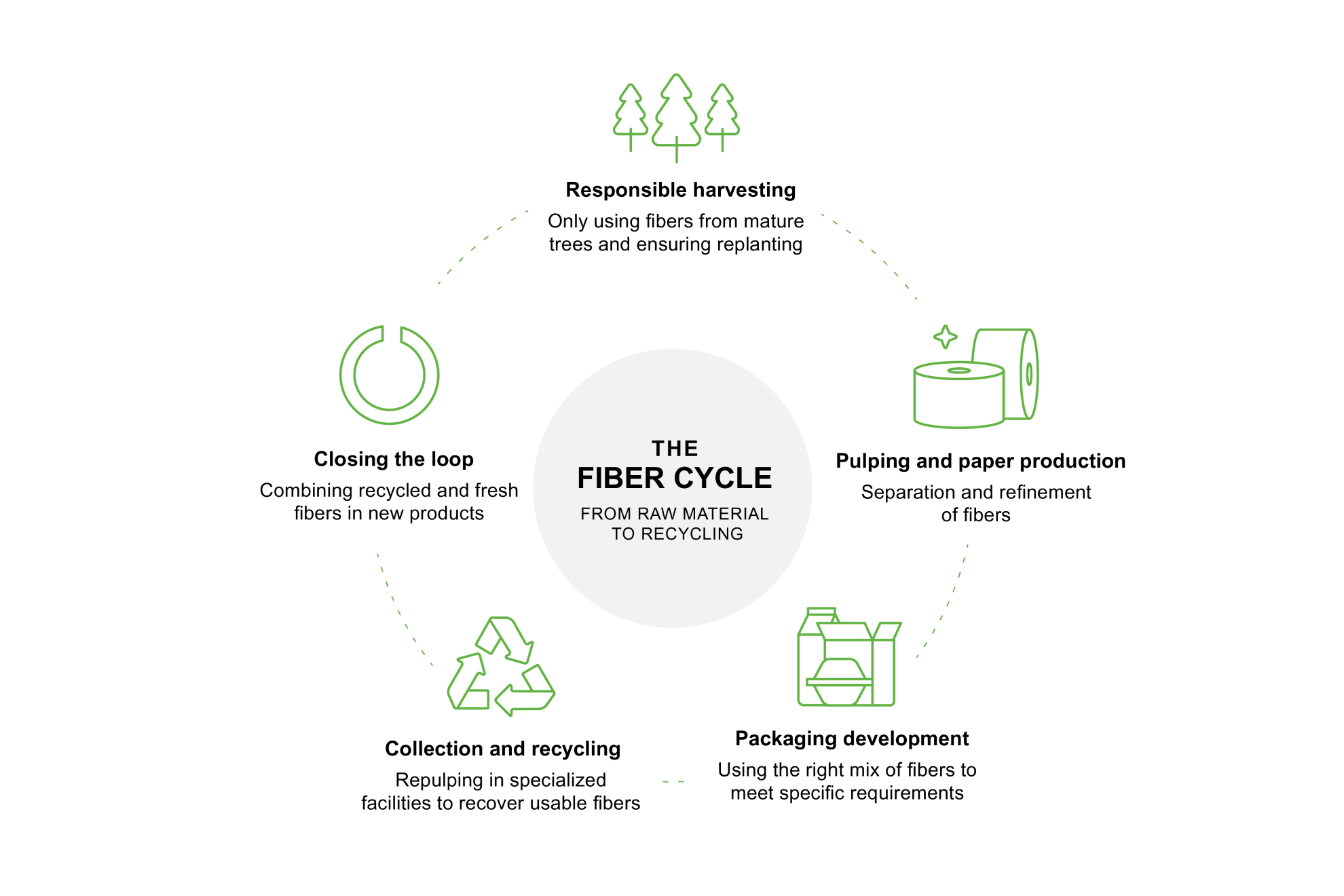

We use fresh fibers from responsibly managed forests in our products. Fresh fibers provide exceptional strength per unit weight, allowing us to meet a certain specification while reducing material use. Smart fiber utilization means using just the right amount of fiber for each type of paper and board. Our development center labs work both independently and alongside customers to develop optimal packaging in terms of performance and weight.

Fiber efficiency is all about precision – delivering exactly what’s needed to meet high performance standards by optimizing fiber usage.

Lightweight packaging offers multiple advantages. Less use of material and lower transport weight reduces the carbon footprint. Packaging producers and buyers achieve a lower total cost of packaging while saving the planet’s resources. A low packaging weight also makes it easier for warehouse staff, store workers and consumers to handle the product.

Long fresh fibers are strong and durable while short fibers are more stiff but also more fragile. The mix of fibers in any given product depends on the performance requirements of the final application. Maintaining a steady supply of fresh fibers is crucial because recycled fibers usually degrade after 5-8 cycles. To keep the fiber cycle sustainable and efficient, new fibers must continuously be introduced into the system.

Optimizing fiber use is about precision and balance – using exactly the right amount for each application. Just as an athlete achieves peak performance by focusing every effort, we strive to make every fiber count.

WHAT FIBER EFFICIENCY IS ABOUT

- Optimize material use

- Reduce carbon footprint

- Support lightweighting

ATHLETIC AMBITION #2:

Finding new and smarter ways

For Billerud’s customers, fast and precise deliveries are critical. Without paper, packaging production grinds to a halt, putting the entire supply chain under pressure. Complicating matters further is our wide product range and large number of customers spread across various locations. As a company driven by sustainability, we also want to ensure that every part of our operations aligns with our environmental goals – logistics is no exception.

In 2022, we took a bold step forward. We analyzed every customer route, re-evaluated our logistics network, initiated discussions with a lot of terminals and made a series of key decisions. The result? A far more flexible and resilient logistics network.

Redesigning the entire European logistics network is an iterative process that requires significant effort. Every part of the system must align, which takes time and continuous improvement. But in the end, it’s worth it.

Unfolded step by step, this new network allows us to handle both everyday logistics challenges (like staff shortages and traffic jams) and more extraordinary disruptions (such as wildcat strikes or severe weather conditions). Railway transportation remains a priority due to its capacity for high volumes and heavy loads with a minimal carbon footprint. At the same time, the increased flexibility in our network opens up new opportunities to further reduce delivery times and emissions.

We continuously measure our logistics performance. Ultimately, effective logistics is about doing less, but with greater impact. The fewer, more focused actions you take, the better the outcome. Just like an athlete’s precision and discipline.

THE NEW LOGISTICS NETWORK

- Streamlined processes for better coordination

- Enhanced agility, flexibility and resilience

- Improved efficiency and reduced emissions

ATHLETIC AMBITION #3:

Ensuring peak performance

The ability to deliver consistent performance is another similarity between top athletes and a company like Billerud. For us, this means maintaining highly efficient production to ensure consistent quality and reliable deliveries to our customers. The basis for this stability is the performance of our paper machines, streamlined work processes, the expertise of our operators and the strong leadership that brings it all together.

In 2022, we launched an initiative to enhance our production processes across all mills. We call this initiative BPS, Billerud Production System. The ambition is to further strengthen our Performance (P) while maximizing Availability (A) and Quality (Q). Together, these factors increase our Overall Equipment Effectiveness (OEE) using the formula OEE = P x A x Q. As the formula suggests, success requires consistently strong performance across the board.

With BPS, we’re taking another step towards more efficient and uniform operations, working closely together. It’s about creating stability in our production, which benefits both us and our customers.

An important aspect of developing BPS was clarifying roles and responsibilities to ensure that current expertise is embedded in our ways of working and preserved for the future. We actively share best practices across all our mills to drive continuous improvement. Through BPS, we aim to create a safer and more efficient work environment, empower every role, enhance customer satisfaction and secure a prosperous future for our mills.

The production system – smarter processes and stronger leadership

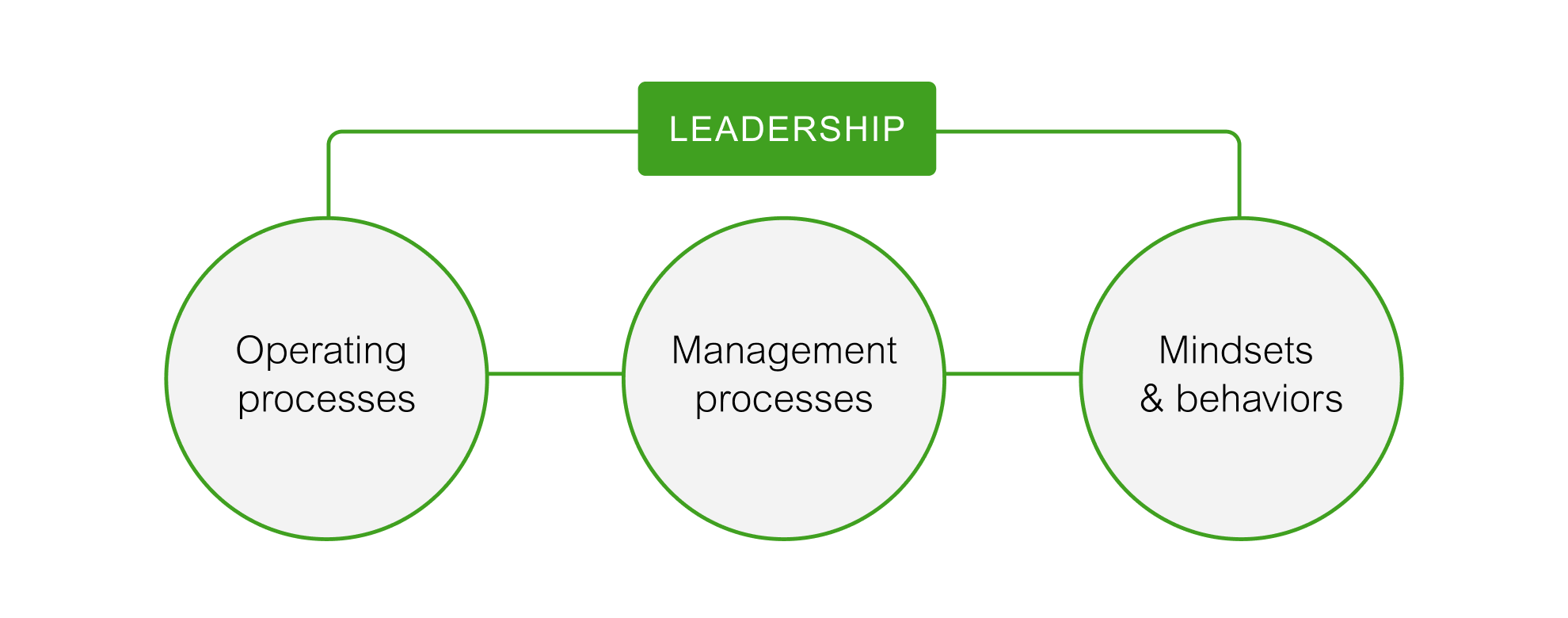

BPS is built on three core pillars: Operating processes, management processes, and mindsets and behaviors. These are connected by strong, unified leadership, symbolized by this illustration.

HOW BPS CREATES STABILITY

- Avoiding costly interruptions

- Ensuring seamless production

- Maximizing efficiency (OEE)